High Quality Needles & Balls

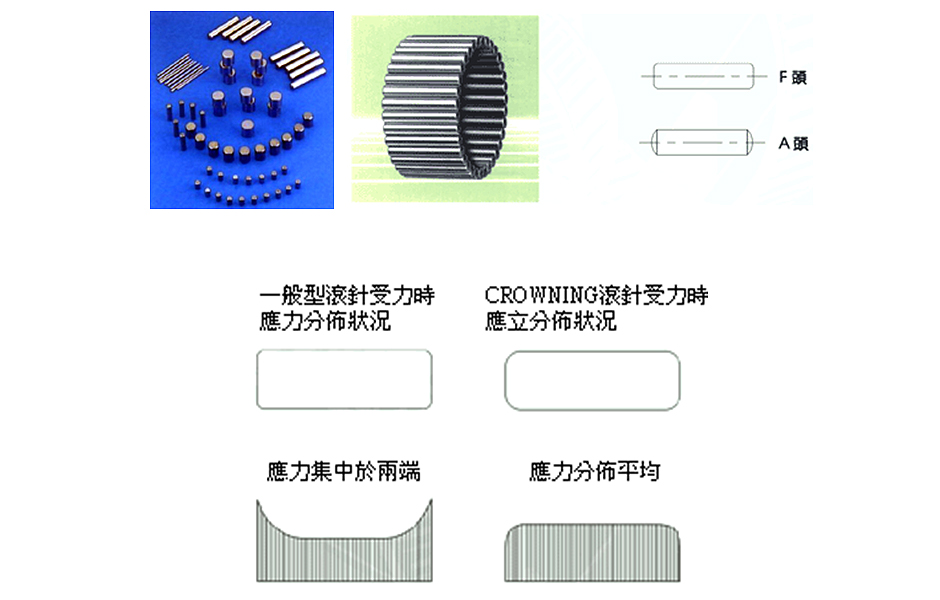

Steel needles are widely used in various processing parts and industrial machinery. The processing range can reach diameters of more than 0.5mm, and the accuracy requirements can reach 2μm. There is absolutely no mixing problem and the heat treatment is uniform. The material is made of bearing steel (JIS SUJ-2/SAE 52100/DIN 100 Cr6) after heat treatment and multiple precision grinding. The hardness is HV 700~860 or above (HRC 60~66). The diameter difference of precision-grade needle rollers is within 0.002 mm, the cylindricality and roundness are within 0.001 mm, and the surface roughness is less than 0.1Ra. CROWNING (also known as controlled contour, or codenamed ZB2) means that the needle roller is deliberately processed into a parabolic correction arc that is difficult to see with the naked eye 1~2 mm close to both ends (as shown in the figure below) ); Its purpose is to ensure an average contact stress between the needle roller and the track surface, so as to avoid high stress at both ends of the needle roller due to stress concentration. The needle roller treated with CROWNING can reduce the maximum stress value on the needle roller and make the load more even, so it can extend the life of the bearing.